NOISE & VIBRATION

Noise in piping system elbows has been shown to result from large scale shed vorticity generated along the flow boundaries in elbows. Elimination of flow separation in elbows will eliminate the accompanying shed vorticity and will result in a larger reduction of fluid induced noise.

The phenomena of elbow generated noise is a result of the forces acting on the fluid as it passes through the elbow, flow separation regions (dead fluid regions) result. Because of the existence of these flow separation regions, the remaining pipe cross-sectional area through which the fluid must pass is significantly reduced and the local velocity is increased and directed toward the outer wall of the elbow. The boundary, between the large inner separation region and the high speed core flow, causes shed vortices that are the source of the large scale turbulence. In a plain elbow there is a high velocity region in the straight section of pipe along the outside of the elbow and a low velocity/backflow region in the straight section of the pipe along the inside of the elbow. The attendant high fluid shear forces in low frequency-large scale shed vorticity is the cause of high noise levels.

In a plain elbow the existence of the separation regions along the outer walls results in a reduced cross-sectional area within the elbow through which the fluid may flow. The situation requires that the fluid accelerate locally in order to get through the elbow. The resulting shear between layers causes two flow separation regions, the remaining cross-sectional area through which the fluid must pass is significantly reduced and the local velocity is increased. The direction of the flow in this region is toward the outer wall downstream of the center of the turn. Thus the elbow acts like a nozzle, accelerating the fluid and directing it toward the outer wall.

A Flow Conditioner allows the fluid to flow through the elbow, without separation and the fluid remains uniform as if the flow was in a straight run of pipe. The flow separation regions are eliminated and the entire cross-sectional area is available for fluid. Elimination of the flow separation and the attendant high fluid shear results in no shed vorticity being developed, hence no noise.

Petro-Equipment Major Oil Company

Experiencing “high axial vibration" on one of their main water feed pumps. The vibration was so bad that it was causing excessive wear on the pump’s impeller and bearings. So much wear in fact that the pump had to be repaired every couple of months; requiring unscheduled expenses for labor, downtime, and parts. Finally, the vibration was so excessive that for safety reasons they had to shut the pump down and bypass it. After reviewing their piping schematic and application, a Flow Conditioner was recommended on the inlet side of the elbow, right before the pump. An immediate improvement in the reduction of vibration. The vibration decreased from 0.84"/sec to 0.54"/sec, a 36% reduction. This was enough reduction in vibration to allow them to start up the pump again, put it in service and use it safely. The pump is still in dire need of repair, and after they repair it (new bearings etc.) next month, we expect the vibration to decrease another 30 to 35% to about 0.30"/sec which is the normal level.

Not only were these flow turbulence problems solved, all applications experienced increased production, better operating efficiencies, less power consumption, and reduced maintenance. Flokinetics can perform a computer flow analysis, engineering expertise and recommend a technology solution to solve your flow turbulence problems.

FLUID HANDLING & FLOW INDUSTRY EXPERTS

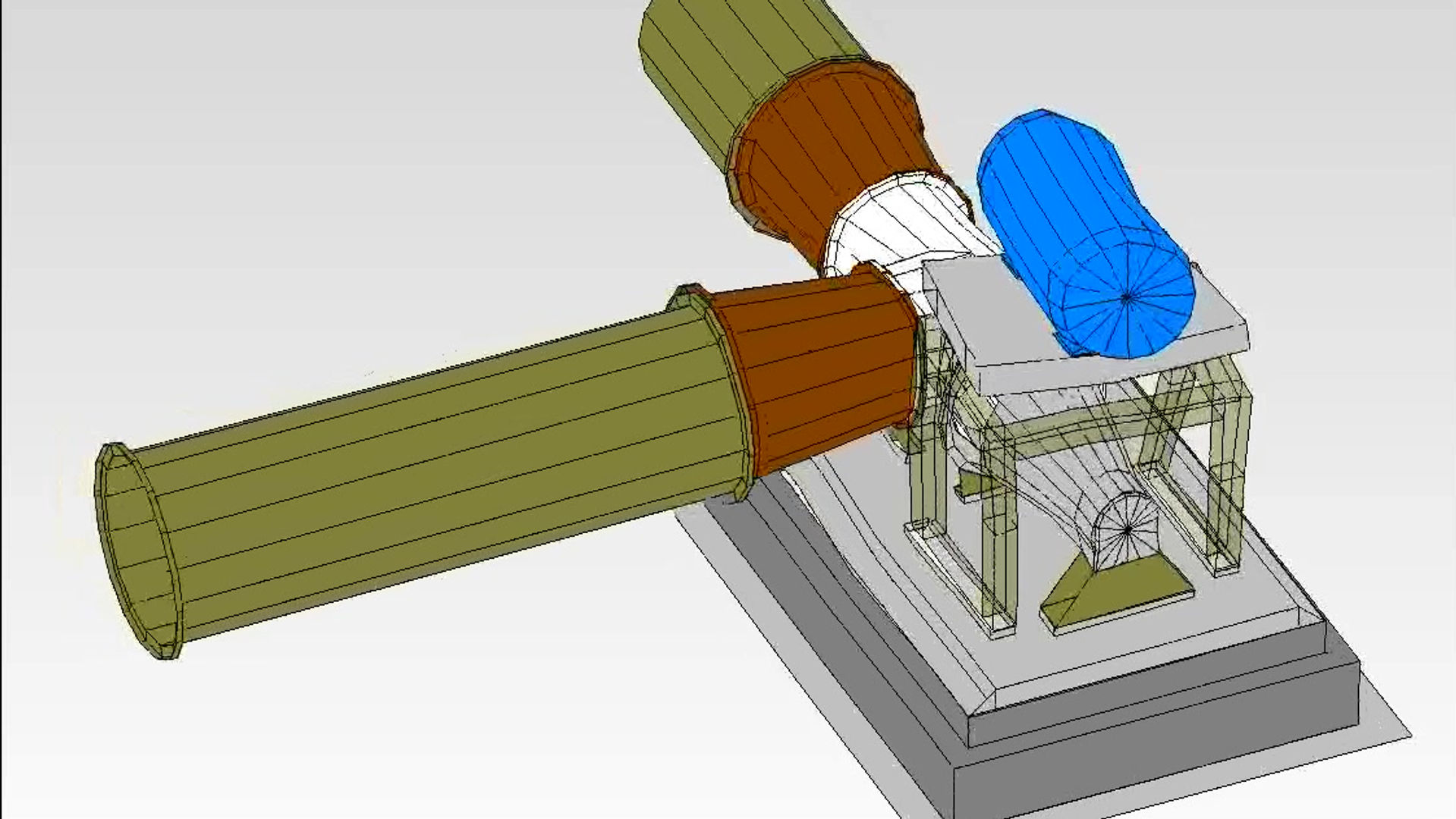

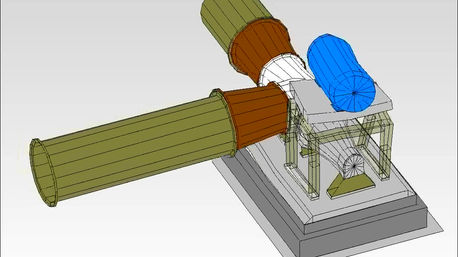

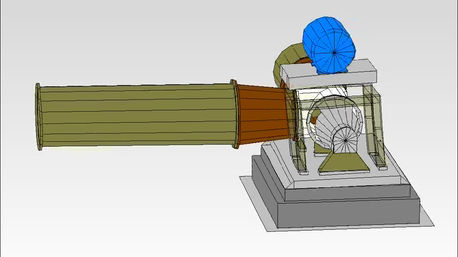

The FLO-TK™ is a stationary solid construction Billet device (of proprietary design) strategically positioned upstream of an elbow or tee to attack the root of the problem by eliminating flow problems from happening. The FLO-TK™ Flow Conditioner is precision manufactured with an aerodynamic design to produce a rotation to cancel out secondary flows and prevent flow separation. Flow problems are prevented by the creation of a uniform laminar flow with increase in NPSH, flow rate, head, velocity, pressure, plant efficiency, industrial safety, parts life extension and reduced maintenance/wear.

Increases Velocity • Aerodynamic Vanes • Airfoil Minimizes Drag • Barrier Designed for Speed • Fluid Meets With Continuity • Eliminates Slow Down Regions • Designed With No Dead Space Regions • High & Low Pressure Regions to Create Lift • Vortex Created To Allow Control of Fluid through Elbow • Flow Conditioner Creates Squeeze to Create Velocity • Areas Can Be Designed to Slow or Speed Fluid • Designed For Long or Short Radius Elbow • For Fluid Transfer & Flow Control • Flow Turbulence Solution • Smooth Laminar Flow • Increases Pressure • Gently Steers Flow • Energy Efficient • No Moving Parts • Rockwell 90 • Easy Retrofit • Billet Machined • Hardened Design • Stationary Device • Solid Construction • Highly Engineered • Proprietary Coatings Available • Corrosion Resistance • Weld or Flanged Ends • Superior Base Material • Precision Manufactured • Hardened Durable Design • Density Absorbent Design • Cost Savings • Installation Payback •